The question is "What is managerial effectiveness?" evokes several responses. There are many responses to this question. Some believe it is an important indicator of the manager's ability to manage people effectively, while others think it is a way to gauge employees' skills. Managers should be compensated for their ability to develop people, and not just deliver results.

Creating a high-performance culture

A high-performance culture requires many elements. Employee engagement is one of the most important. Employees who feel like they have a say in how the company operates are more likely to perform well. Fostering a culture that encourages collaboration and inclusion is another key element. People who work in diverse teams are more productive, and organizations which promote diversity are more likely be to provide opportunities for those communities that are underrepresented.

Employees who work in high-performance environments are more likely than others to take responsibility for their work. They also feel aligned with their organization's vision and values. This kind environment fosters trust between teams and encourages them to work together in order to achieve their goals.

Create a performance management program

Establishing a performance management process is an ongoing effort that involves feedback and communication. While the process has traditionally focused on quarterly evaluations and rewards, modern business practices are embracing continuous feedback and guidance. It can help organisations prevent potential problems from occurring and to address any performance concerns. A performance management system can benefit any organization with employees. It's especially useful for managers and leaders of teams.

The Balanced Scorecard or BSC is one of the most powerful systems. It's a powerful management tool that allows managers across departments to align their goals. BSC allows managers and leaders to link the objectives of their departments to the larger organization's goals. By combining measures and initiatives, managers can better understand how their employees are performing against their responsibilities.

To have a successful performance management system, employees must be encouraged to learn and develop. This will help employees reach their full potential. A well-designed system is easy to use in all departments. It also sets consistent expectations for all staff. It can also be flexible to enable managers recognize and assess great talent, as well as determine training needs.

Assessing the performance of a manager

You should consider many factors when evaluating a manager's performance. This includes how they give feedback and how information is communicated. You should also consider the impact that the manager's actions are having on your employees' performance. These aspects of leadership can have a major impact on employee engagement and company performance.

The first step in the process of evaluating a manager's performance is to establish the purpose of the assessment. If the purpose is to identify areas that need improvement, the process of assessing a manager's performance can be very effective. Managers should conduct a performance review to determine what's working and where there are opportunities to improve. However, this assessment process can be challenging. It's important not to forget that this is an enterprise decision. The review goals and metrics should be aligned against the company's objectives.

Another key aspect of assessing a manager's performance is to determine whether they are a good leader. This means they need to know how to set clear expectations for their employees and give them clear direction. They should also understand how to communicate information to employees and hold them accountable for achieving their goals. They should also be able to motivate and engage employees to improve their professional skills.

FAQ

How does a manager motivate their employees?

Motivation is the desire for success.

You can get motivated by doing something enjoyable.

You can also be motivated by the idea of making a difference to the success and growth of your organization.

You might find it more rewarding to treat patients than to study medical books if you plan to become a doctor.

Another source of motivation is within.

You might feel a strong sense for responsibility and want to help others.

You might even enjoy the work.

If you don’t feel motivated, find out why.

Then, consider ways you could improve your motivation.

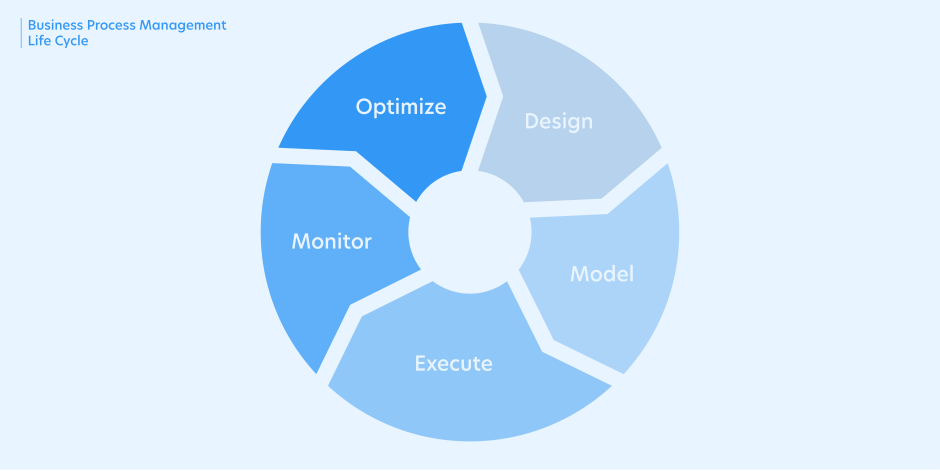

What are the five management methods?

These five stages are: planning, execution monitoring, review and evaluation.

Planning involves setting goals for the future. This includes setting goals for the future and defining what you want.

Execution is when you actually execute the plans. You need to make sure they're followed by everyone involved.

Monitoring is a way to track progress towards your objectives. Regular reviews should be done of your performance against targets or budgets.

Reviews take place at the end of each year. They provide an opportunity to assess whether everything went well during the year. If not then, you can make changes to improve your performance next year.

Following the annual review, evaluation is done. It helps identify what worked well and what didn't. It provides feedback about how people perform.

What is Kaizen and how can it help you?

Kaizen refers to a Japanese term that stands for "continuous improvements." It is a philosophy which encourages employees in continuously improving their work environment.

Kaizen is founded on the belief of everyone being able to do their job well.

What is Six Sigma?

It's a strategy for quality improvement that emphasizes customer care and continuous learning. The goal is to eliminate defects by using statistical techniques.

Motorola created Six Sigma as part of their efforts to improve manufacturing processes in 1986.

This idea quickly spread throughout the industry. Today, many organizations use six sigma methods for product design, production and delivery.

What is a basic management tool used in decision-making?

The decision matrix is a powerful tool that managers can use to help them make decisions. They can think about all options and make informed decisions.

A decision matrix allows you to represent alternatives as columns and rows. This allows one to see how each alternative impacts other options.

We have four options in this example. They are represented by the boxes to the left of the matrix. Each box represents an option. The top row displays the current situation, and the bottom row shows what might happen if nothing is done.

The middle column shows the effect of choosing Option 1. This would result in an increase of sales of $2 million to $3million.

The following columns illustrate the impact of Options 2 and 3. These are good changes, they increase sales by $1million or $500,000. These changes can also have negative effects. Option 2 increases the cost of goods by $100,000. Option 3 decreases profits and makes them less attractive by $200,000.

The last column displays the results of selecting Option 4. This would result in a reduction of sales of $1 million.

The best part of using a decision-matrix is that it doesn't require you to know which numbers belong where. You just look at the cells and know immediately whether any given a choice is better than another.

This is because the matrix has done all the hard work. It is as simple a matter of comparing all the numbers in each cell.

Here is an example of how a decision matrix might be used in your business.

You need to decide whether to invest in advertising. If you do this, you will be able to increase revenue by $5000 per month. But, you will also incur additional expenses of $10 thousand per month.

If you look at the cell that says "Advertising", you can see the number $15,000. Advertising is worth much more than the investment cost.

Statistics

- The average salary for financial advisors in 2021 is around $60,000 per year, with the top 10% of the profession making more than $111,000 per year. (wgu.edu)

- 100% of the courses are offered online, and no campus visits are required — a big time-saver for you. (online.uc.edu)

- Your choice in Step 5 may very likely be the same or similar to the alternative you placed at the top of your list at the end of Step 4. (umassd.edu)

- Hire the top business lawyers and save up to 60% on legal fees (upcounsel.com)

- The BLS says that financial services jobs like banking are expected to grow 4% by 2030, about as fast as the national average. (wgu.edu)

External Links

How To

How does Lean Manufacturing work?

Lean Manufacturing techniques are used to reduce waste while increasing efficiency by using structured methods. They were developed by Toyota Motor Corporation in Japan during the 1980s. The aim was to produce better quality products at lower costs. Lean manufacturing focuses on eliminating unnecessary steps and activities from the production process. It includes five main elements: pull systems (continuous improvement), continuous improvement (just-in-time), kaizen (5S), and continuous change (continuous changes). Pull systems are able to produce exactly what the customer requires without extra work. Continuous improvement means continuously improving on existing processes. Just-in-time refers to when components and materials are delivered directly to the point where they are needed. Kaizen means continuous improvement. Kaizen involves making small changes and improving continuously. Last but not least, 5S is for sort. These five elements can be combined to achieve the best possible results.

Lean Production System

Six key concepts make up the lean manufacturing system.

-

Flow is about moving material and information as near as customers can.

-

Value stream mapping: This is a way to break down each stage into separate tasks and create a flowchart for the entire process.

-

Five S's - Sort, Set In Order, Shine, Standardize, and Sustain;

-

Kanban – visual signals like colored tape, stickers or other visual cues are used to keep track inventory.

-

Theory of constraints - identify bottlenecks during the process and eliminate them with lean tools like Kanban boards.

-

Just-in Time - Send components and material directly to the point-of-use;

-

Continuous improvement - Make incremental improvements rather than overhauling the entire process.