Time boxing can be used to manage time efficiently and effectively. It involves setting time limits for your team members to accomplish tasks. Once everyone on a team has agreed that they will work within the given timeframe, it is possible to assign tasks and encourage more organization. At the end of a time box, the team should review their progress and decide what steps they need to take to finish the task. Here are some benefits as well as challenges to time boxing.

David Sherwin's lessons

David Sherwin's Timeboxing method is an excellent way to ensure you're getting more done and less time. This is done by assigning very specific tasks in small blocks of your time. Each task can have its time box. You can also allow yourself some leeway in planning how long it'll take.

The technique is also great for brainstorming. It can make a complex problem more manageable. It helps to break down a complicated design problem into smaller parts. It allows you to allocate time for each task, and then evaluate your progress.

Benefits

Time boxing, a powerful tool for staying focused and preventing procrastination, is very effective. It also reduces distractions. You can also block certain websites and disable notifications, which will allow you to be productive and not waste your time. Time boxing, unlike other methods that can cost money or take up too much time to implement, is simple and free.

Time boxing is a great way to make more time and feel like you're moving forward. This technique can also help you overcome project paralysis. This method helps you break down a big task into manageable chunks, such as creating marketing plans. You can also mark each task on your calendar to see how long you spent on it.

Challenges

Time boxing is a method for increasing productivity in a short amount of time. It can be used for many tasks, including writing articles. Setting realistic goals is key when time-boxing. Writers should strive to produce 1,000 words per hour in time-limited situations.

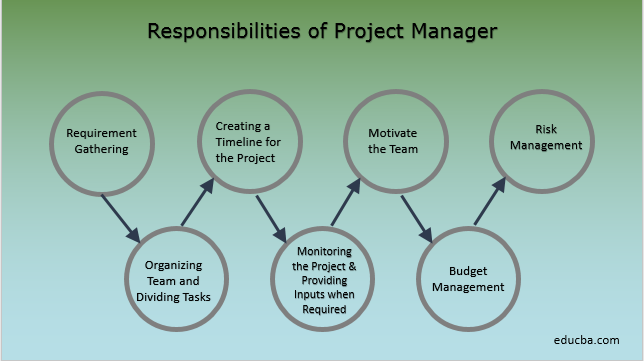

Although time boxing can be a great way to improve work-life balance and productivity, it does have its challenges. The best time boxing results are achieved when the team works together and has a clear plan for the day. This helps prevent long meetings that can delay deliverables, cause poor quality work, and extend work hours. The time boxing system helps team members to be accountable for the time they have been allotted. Time boxing can be broken by any member of the team. A team member can redirect them to another task.

Implementation

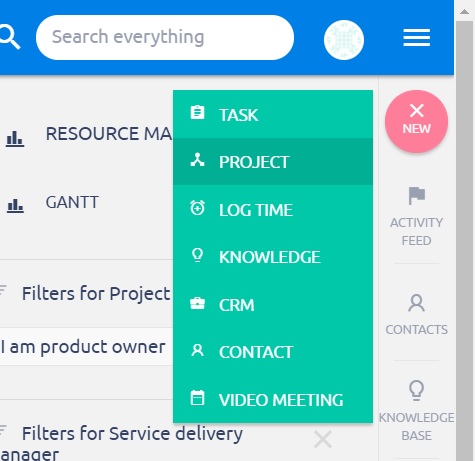

Time boxing is a technique for time management that helps people focus on a single task and use their time effectively. It also helps people manage their priorities. Effective time boxing is a way to complete tasks quickly and efficiently. But, time boxing works only when you are focused on the task within the given time. Tools that allow you to set a timer can help you stay focused.

You must first choose the task for which you will use time boxing. It's worth considering its importance, its time frame, and whether the task will have any value. This will allow you to determine a realistic start date. Otherwise, you'll end up working longer than you thought.

FAQ

What kind people use Six Sigma?

Six Sigma will most likely be familiar to people who have worked in statistics and operations research. However, anyone involved in any aspect of business can benefit from using it.

Because it requires a high degree of commitment, only leaders with strong leadership skills can implement it successfully.

What does Six Sigma mean?

Six Sigma uses statistical analysis for problems to be found, measured, analyzed root causes, corrected, and learned from.

The first step is to identify the problem.

The data is then analyzed and collected to identify trends.

The problem can then be fixed by taking corrective measures.

Finally, the data are reanalyzed in order to determine if it has been resolved.

This cycle continues until the problem is solved.

How does a manager motivate their employees?

Motivation refers to the desire to perform well.

It is possible to be motivated by doing something you enjoy.

You can also feel motivated by making a positive contribution to the success in the organization.

You might find it more rewarding to treat patients than to study medical books if you plan to become a doctor.

A different type of motivation comes directly from the inside.

For example, you might have a strong sense of responsibility to help others.

Maybe you like working hard.

If you don't feel motivated, ask yourself why.

Then think about how you can make your life more motivating.

Statistics

- As of 2020, personal bankers or tellers make an average of $32,620 per year, according to the BLS. (wgu.edu)

- 100% of the courses are offered online, and no campus visits are required — a big time-saver for you. (online.uc.edu)

- The BLS says that financial services jobs like banking are expected to grow 4% by 2030, about as fast as the national average. (wgu.edu)

- The profession is expected to grow 7% by 2028, a bit faster than the national average. (wgu.edu)

- Our program is 100% engineered for your success. (online.uc.edu)

External Links

How To

How is Lean Manufacturing done?

Lean Manufacturing methods are used to reduce waste through structured processes. They were developed in Japan by Toyota Motor Corporation (in the 1980s). The aim was to produce better quality products at lower costs. Lean manufacturing eliminates unnecessary steps and activities from a production process. It consists of five basic elements: pull systems, continuous improvement, just-in-time, kaizen (continuous change), and 5S. Pull systems are able to produce exactly what the customer requires without extra work. Continuous improvement means continuously improving on existing processes. Just-in time refers to components and materials being delivered right at the place they are needed. Kaizen means continuous improvement. Kaizen involves making small changes and improving continuously. The 5S acronym stands for sort in order, shine standardize and maintain. These five elements work together to produce the best results.

Lean Production System

Six key concepts underlie the lean production system.

-

Flow: The goal is to move material and information as close as possible from customers.

-

Value stream mapping - break down each stage of a process into discrete tasks and create a flowchart of the entire process;

-

Five S's: Sort, Shine Standardize, Sustain, Set In Order, Shine and Shine

-

Kanban - visual cues such as stickers or colored tape can be used to track inventory.

-

Theory of constraints - identify bottlenecks during the process and eliminate them with lean tools like Kanban boards.

-

Just-in time - Get components and materials delivered right at the point of usage;

-

Continuous improvement - make incremental improvements to the process rather than overhauling it all at once.