What is the definition of management of change? Methodical approaches to managing change are part of the definition of management of changes. This includes supporting change, preparing for it, and helping people, groups, and organizations deal with it. As the name suggests, the term 'change' is disruptive to the daily operation of a business. It is also a multidisciplinary field and encompasses many disciplines. Learn more. This article will give an overview of the term.

Change management is a systematic approach to managing changes

Management of major changes is critical when people or groups of people face significant change. Many people view change management as a simple matter of communicating a message. But it's much more than that. Change management includes the implementation of corporate strategies, processes, procedures, as well leading the people aspect of major organizational changes. By implementing new products, processes and technologies, change management aims to reduce negative effects and increase chances of success.

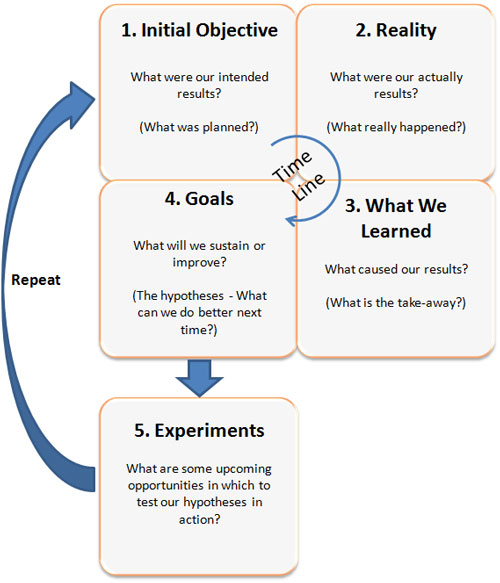

It is about measuring the progress of an improvement.

Measurement is an important element of change management. All structured change initiatives, including organizational change, include some form of measurement. A project's success could be measured, for instance, by measuring whether the project goal was met within budget and on time. However, most change management practitioners don't measure the project's success in terms of its outcomes. Instead, they report on participants' performance by examining their change management activities.

It can disrupt normal operations

Disruption has become a part of daily life. It is a reality that organizations are constantly facing. It is vital that leaders plan for this change and ensure that it is implemented in a way that maximizes the organization's benefits. Managers should assess the potential impact of their organization and evaluate their capabilities and resources to do this. These resources include non-physical ones such as information and product design, brand, interdepartmental relationships, public relations, etc.

It requires enough resources

Effective management includes planning, implementing, monitoring, and tracking the change. For successful management to be effective, people must be engaged, mobilized, and tracked for progress. The Human Side of Change Leadership identifies the possible reasons that a planned change will fail, and how to design motivation into the new process. If the change management model fails to work, you will see 15 common waste scenarios. These scenarios show what can go wrong, and why.

FAQ

What does it mean to say "project management"

We mean managing the activities involved in carrying out a project.

This includes defining the scope, identifying the requirements and preparing the budget. We also organize the project team, schedule the work, monitor progress, evaluate results, and close the project.

What are management concepts?

Management Concepts are the principles and practices managers use to manage people and resources. These include topics such as human resource policies and job descriptions, performance assessments, training programs and employee motivation.

What is the difference between TQM and Six Sigma?

The major difference between the two tools for quality management is that six Sigma focuses on eliminating defect while total quality control (TQM), on improving processes and decreasing costs.

Six Sigma is a method for continuous improvement. It emphasizes the elimination and improvement of defects using statistical methods, such as control charts, P-charts and Pareto analysis.

This method aims to reduce variation in product production. This is done by identifying and correcting the root causes of problems.

Total quality management is the measurement and monitoring of all aspects within an organization. It also involves training employees to improve performance.

It is often used as a strategy to increase productivity.

How do you define Six Sigma?

Six-sigma will be well-known to anyone who has worked in operations research or statistics. But anyone can benefit from it.

Because it requires a high degree of commitment, only leaders with strong leadership skills can implement it successfully.

Statistics

- Hire the top business lawyers and save up to 60% on legal fees (upcounsel.com)

- The profession is expected to grow 7% by 2028, a bit faster than the national average. (wgu.edu)

- UpCounsel accepts only the top 5 percent of lawyers on its site. (upcounsel.com)

- This field is expected to grow about 7% by 2028, a bit faster than the national average for job growth. (wgu.edu)

- Our program is 100% engineered for your success. (online.uc.edu)

External Links

How To

What is Lean Manufacturing?

Lean Manufacturing is a method to reduce waste and increase efficiency using structured methods. They were created in Japan by Toyota Motor Corporation during the 1980s. The main goal was to produce products at lower costs while maintaining quality. Lean manufacturing seeks to eliminate unnecessary steps and activities in the production process. It is composed of five fundamental elements: continuous improvement; pull systems, continuous improvements, just-in–time, kaizen, continuous change, and 5S. The production of only what the customer needs without extra work is called pull systems. Continuous improvement is constantly improving upon existing processes. Just-in time refers to components and materials being delivered right at the place they are needed. Kaizen stands for continuous improvement. Kaizen can be described as a process of making small improvements continuously. Fifth, the 5S stand for sort, set up in order to shine, standardize, maintain, and standardize. These five elements work together to produce the best results.

The Lean Production System

Six key concepts are the basis of lean production:

-

Flow - focus on moving material and information as close to customers as possible;

-

Value stream mapping is the ability to divide a process into smaller tasks, and then create a flowchart that shows the entire process.

-

Five S's - Sort, Set In Order, Shine, Standardize, and Sustain;

-

Kanban: Use visual signals such stickers, colored tape, or any other visual cues, to keep track your inventory.

-

Theory of constraints: Identify bottlenecks and use lean tools such as kanban boards to eliminate them.

-

Just-in Time - Send components and material directly to the point-of-use;

-

Continuous improvement - Make incremental improvements rather than overhauling the entire process.